Ozone decomposer OZ-1000

We have developed a high-efficiency ozone decomposer “OZ-1000”.

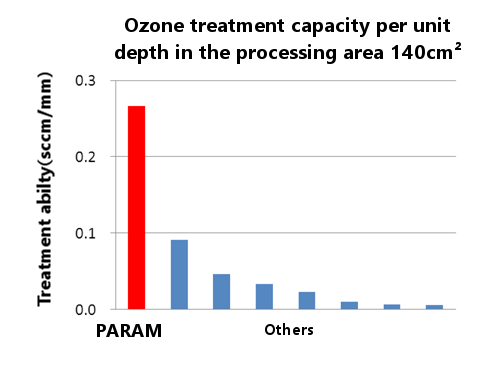

We developed new material that can decompose ozone gas.

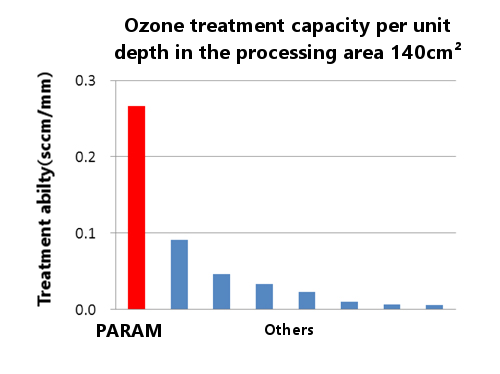

New material's performance is several times higher than conventional material zeolite.

So this ozone decomposer is smaller than other company's conventional ozone decomposer.

OZ-1000 has same conductance as conventional ozone decomposer.

Our ozone decomposer OZ-1000’s performance is higher more than conventional ozone decomposer.

OZ-1000

OZ-1000L

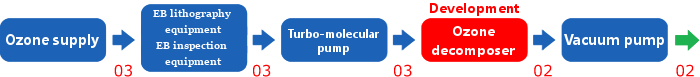

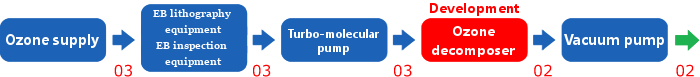

- The ozone decomposer is required in order to prevent the outflow of the high concentration ozone gas to downstream.

- Ozone removal tool is required to prevent the vacuum pump corrosion by ozone gas. Especially the TMP's back-pressure pump has high pressure ozone gas. The ozone decomposer is essential .

- Dust-rich material like an activated carbon cannot be used to guard the vacuum pump. We developed the ozone decomposer that does not use it.

PAGE TOP

Ozone treatment capability evaluation of chemical material

Ozone monitor A051020-SP61-01F(FIS)

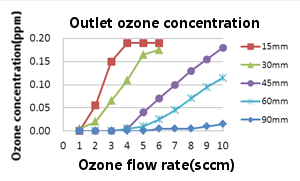

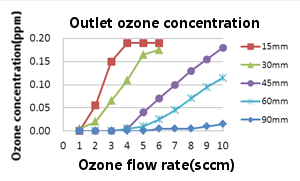

Evaluation the throughput of decomposing ozone by changing the depth of the chemical material (Cross-section is Φ134mm:140cm2)

- In the left view: Depth of quantity of a chemical material becomes the deeper, the leakage of the ozone undecomposed reduces even in a large flow rate. Chemical material depth of OZ-1000 is 60mm. Therefore ozone gas is decomposed to below 0.1ppm (TLV) at 5sccm.

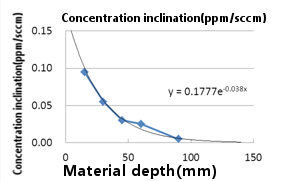

- In the right view: If we assume that the inclination of the line in the evaluation value of the concentration of ozone gas (ppm / sccm), concentration inclination decreases almost exponentialy of depth of chemical material.

- If the depth the chemical material is 140mm, ozone gas of concentration 0.09ppm can be processed at the 100sccm.

→ Reflected in the OZ-1000L of chemical material depth 180mm (0.02ppm)

※Depth will shallow without notice by the technology progress .

PAGE TOP

Contact

PARAM Corporation

Excel Bldg., 3F. 4-44-4 Dai-machi, Hachioji-shi, Tokyo 193-0931 Japan

【Phone】 (+81) 42-629-9852

【Fax】 (+81) 42-629-9862

→Mail

PAGE TOP